How can performance be enhanced in a single ply roofing system build-up?

How can performance be enhanced in a commercial single ply roofing system build-up?

Single ply roof system build-ups have become popular in recent years due to their low cost and relatively easy installation, but there can be performance drawbacks to low slope or flat roof systems with single ply. This blog will consider the benefits of roof cover boards and look closer at how these can help address some of the common challenges of single ply roofing systems build ups.

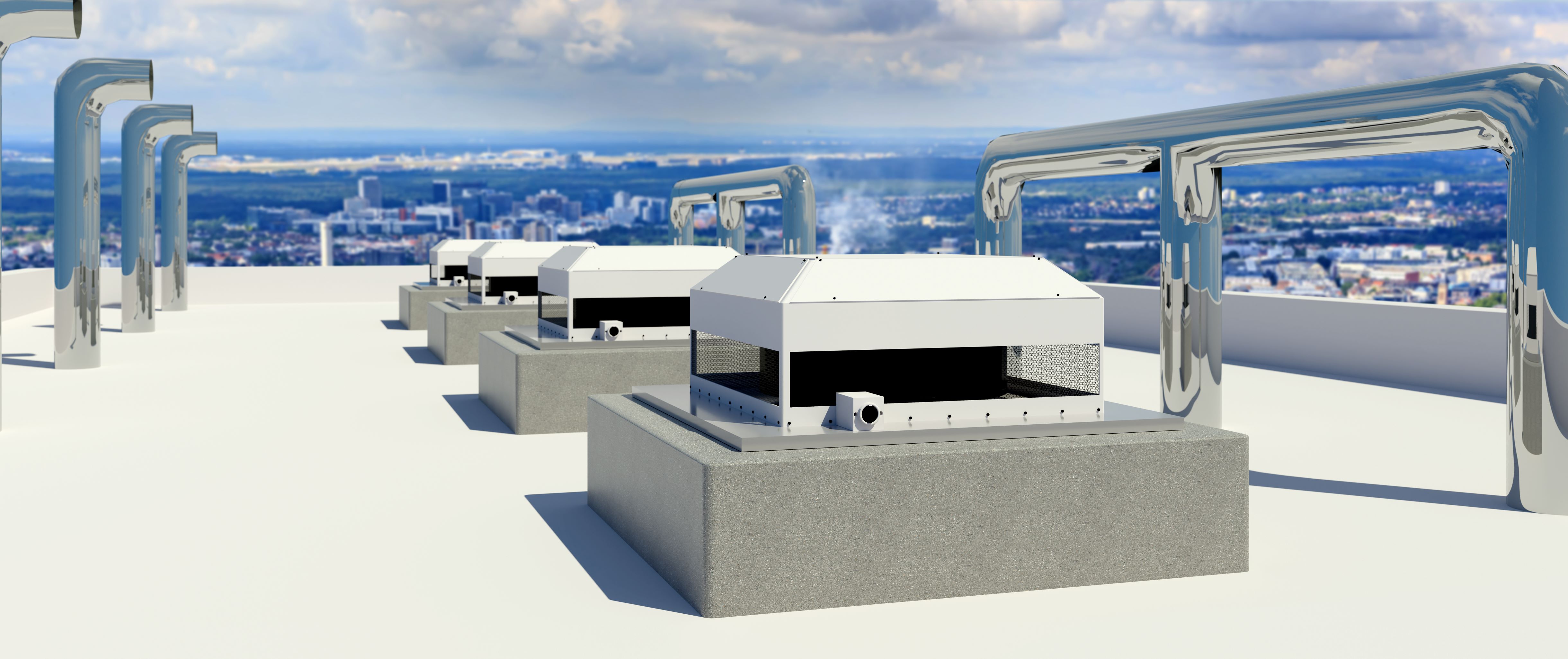

The emphasis for modern flat roof systems, especially in the commercial sector, is on durability, performance, cost, and speed of construction. Whilst single ply delivers on most of these points, one of the challenges is roof access. Lack of access can be problematic for data centre flat roofs or biotech flat roofs that have many building services requiring frequent maintenance. Single ply can also be prone to puncture through adverse weather such as repeated heavy hailstorms, flying debris or accidental human interaction. Dropped tools fall into the latter category.

Another challenge is durability. Single ply requires installation by competent teams. This is because the better the bond between the waterproof membrane and the substrate, the longer the roof membrane can perform its most crucial function, keeping the moisture out of the building envelope.

To summarise, there are five areas single ply roof build up needs to address to ensure maximum performance:

- Roof access for regular maintenance

- Membrane puncture resistance

- Robust substrate for improved adhesion

- Wind uplift performance

- Fire performance

This blog will look at the last two in the list: wind uplift and other weather protection and fire resistance.

Before we do, so we will consider what cover boards are.

What are cover boards?

Cover boards are thin boards made of materials such as wood, cement, or gypsum installed over the insulation layer and below the waterproofing layer of flat or low slope roof systems.

Whilst wood has been the traditional cover board, be it the timber or engineered timber alternatives, modern construction favours two types of boards: cementitious and mat faced gypsum core cover boards. We have previously covered each type’s performance benefits and advantages in our blog Cement or fibreglass mat gypsum board for roof protection. The performance benefits of both types of cover boards are quite closely matched. The most significant differences are the weight, ease of installation and material compatibility. Mat faced gypsum core cover boards are considerably lighter and can be customised using standard tools. The installation is relatively easy. High performance mat faced gypsum cover boards such as DensDeck® Roof Boards have a coated glass mat facer on both sides, increasing material compatibility with adhesives. This is crucial to ensuring quality installation that results in durable single ply roofing systems.

Can cover boards help with roof traffic on roofs with single ply membranes?

As we mentioned at the start of this blog, one of the drawbacks of single ply roof membranes can be roof access. Occasional, light roof traffic is unlikely to damage the single ply roof membrane. However, modern commercial buildings feature a large number of building services, and these are often installed on roofs. The continuous operation of HVAC (heating, ventilation and air conditioning) and other building services is crucial for running data centres and biotech. The higher intensity of maintenance requirements of these systems translates into an increased frequency of foot traffic. This carries a risk of damage to the single ply roof membrane. The roof build up design should reflect this, and the use of roof access boards is one measure that can reduce the risk of damage to the membrane.

DensDeck® Roof Boards have high flexural, compressive, and static strength. This means that they can help the roof assembly withstand maintenance footfall. Using a roof cover board provides increased foot traffic resistance to the roof assembly helping to spread any compressive load across the insulation – typically the most expensive part of any roof system.

It is worth noting that single ply membranes can become slippery in wet or cold weather. It is good practice to overlay the single ply with a walkway membrane in areas where all year access is required to help increase safety.

Can cover boards help minimise the risk of punctures to single ply membranes?

Although punctures to single ply membranes are relatively easy to repair, they pose a risk of moisture ingress that could damage the building envelope, cause operation downtime in commercial buildings, and damage stock and equipment.

Common causes of roof membrane punctures are repeat hailstone strikes, albeit they are still relatively rare in the UK, flying debris and most often accidentally dropped tools. The even surface of the DensDeck® Roof Board forms a platform that helps support the waterproofing membrane from accidental penetration.

How can I increase the robustness and longevity of a single ply roof membrane build up?

Cover boards provide a stable, flat, and strong surface to which a waterproofing membrane can be mechanically fixed or adhered. The flat cover board helps remove any surface irregularities. This results in better adhesion for adhered single ply membranes, improving the aesthetic impact of the finished roof.

We already mentioned coated glass mat facers embedded on the top and bottom of the DensDeck® Roof Board. The mat facers promote an equal and homogenous spread of adhesives. This, in turn, can result in a stronger bond with the single ply roof membrane.

These mat facers also increase material compatibility with most types of commonly used adhesives without the need for priming. This can help prevent the single ply roof membrane blistering and can speed up the single ply installation process.

Can a cover board increase the wind uplift resistance of a single ply roof?

Wind uplift can cause severe damage to flat and low slope roofs. We have already touched upon the fact the cover boards act as a substrate that helps improve the bond strength with the roof membrane. This, in turn, can enhance wind uplift resistance of the roof build up.

The same is true of mechanically fixed membranes. Here the cover board provides a stable platform for fasteners. Provided the cover board manufacturer recommended fastener pattern is adhered to, this can help improve the wind uplift resistance of mechanically fixed single ply membranes.

In addition, DensDeck® Roof Board helps absorb differential movement caused by wind uplift. This can play a significant role in protecting the waterproofing membrane and roof system. FM Approvals tested a variety of roof assemblies with DensDeck® Roof Boards. A quick interrogation of FM Approvals’ RoofNav database reveals approved assemblies with a wind uplift rating of up to 43.8kPa (915psf).

Can DensDeck® Roof Board improve the fire resistance of single ply roofs?

When it comes to fire resistance, DensDeck® Roof Boards can be installed in two positions in a roof system:

• Roof board: above the roof deck and below the insulation layer

• Cover board: above the insulation layer and below the single ply membrane

When installed as a cover board, they can help improve the resistance of the roof system to attack from external fire sources. Fire resistant roof boards can help slow the spread of internal fires when installed as a roof board.

DensDeck® Roof Boards have an A1 fire classification in accordance with BS EN 13501-1 and are classified as non-combustible as described and tested in accordance with ASTM E136 and CAN/ULC S114. They have been included in over 195,0001 roofing assemblies as roof boards with a Factory Mutual (FM) Class 1 fire rating from inside the building. There are 368,611 roof assemblies containing DensDeck® Roof Boards in a cover board position that achieve FM Class A fire performance from outside the building. This makes DensDeck® Roof Boards suited for specification as fire performance boards in mission critical sectors and crucially in buildings designed for public use.

Contact us to find out more about the benefits of DensDeck® Roof Boards and how they can improve the performance of your single ply membrane roof system for your project.

1 Audit carried out on 16th August 2023

Contact Us

Start your project or simply get specification advice by dropping us a message.

One of our team will be in touch as soon as possible.