DensDeck® Roof Boards Specified as Part of an Award-Winning Acoustic Solution for Lionsgate Studios in Yonkers, New York

An intricate design of roofing materials, including three layers of DensDeck® Roof Boards and a further two layers of DensDeck® Prime Roof Boards, were specified to overcome the acoustic challenge faced by the roof of a new soundstage building – with award-winning results.

The 90 Warburton soundstage building is on the state-of-the-art Lionsgate Studios complex 11 miles away from midtown Manhattan. The campus, situated along the Hudson River, opened in 2022. It is owned and operated by Great Point Studios and forms part of their 500-million-dollar development, with plans that include a total of 11 soundstages and parking for more than 750 cars and 100 trucks1. This expansion is needed to fill a shortage of large purpose-built stages and is welcomed by the city of Yonkers which is billing itself to become the “Hollywood on the Hudson.”2

The new sound stage was the second to be built on the Lionsgate Studios campus, located in close proximity to the New York rail tracks. Construction of a third production space, housing three sound stages for Mediapro Studios is underway at the North Broadway campus in Yonkers and is due to open in the autumn of 2024.

When the first building was constructed, the unexpected impact of the noise generated by passing trains on studio productivity was not anticipated. The noise proved to be so disruptive that filming had to be scheduled around the very busy local train timetables.

More than 150 trains passed the studio each day and either stopped at, or travelled through, the nearby Yonkers train station. The low rumbling sounds of the trains on the tracks and the higher pitched sounds of train horns blown when passing through the station, were making their way into the studio building and affecting the sound quality on the sets.

Some remedial work was carried out to try to reduce the impact of the external noise by fitting acoustic insulation at the ceiling level. However, a studio building needs a ceiling with a clear and open span height to allow access for rigging to suspend lighting and filming equipment. This ruled out the installation of a false ceiling and therefore limited the quantity and effectiveness of the acoustic measures that could be implemented. Therefore, when the material specification of the second studio was drawn up, the client understandably had a keen focus on its acoustic performance, especially on sound attenuation.

The work required on the first studio was a good driver for the design needed for Lionsgate as Joe Donnelly, Technical Sales Specialist, Rockwool explains: “The difficulties encountered when trying to remediate the acoustic difficulties at ceiling level showed that the best option was to create a robust roof assembly above the roof deck. This would keep the sound of the trains out and allow the ceiling inside the studio to be used as originally designed.”

Lionsgate set an ambitious acoustic target for the 2800 m2 (30,000 sq.ft) roof of the new studio, by requiring the build-up to achieve an STC (Sound Transmission Class) rating of 55. The STC is measured in decibels and is the weighted average of the drop in sound intensity measured in a range of frequencies from 80 to 5,000 Hz across a barrier.

Eligator Acoustics Associates worked together with product manufacturers Rockwool and Georgia-Pacific (manufacturer of DensDeck® Roof Board) and the main roofing contractor Nations Roof, to create a bespoke specification that would achieve the challenging target. The material specification needed to meet both the exacting acoustic requirements of the customer and create a resilient roof design.

The five layers of DensDeck® Roof Boards helped to reduce external sound transmission and provided a robust supporting layer for the adhered TPO waterproof membrane, increasing the weather resilience of the roof as well as improving its acoustic performance.

John Geary, Chief Marketing Officer of Nations Roof, had this to say about the roof build-up: “The roof area was relatively small at 30,000 sq ft however the build-up was around 11 inches thick. I am pleased to say we rose to the logistical challenge of getting all the materials on the roof in a very busy street without disrupting the traffic flow.”

How did DensDeck Roof Boards contribute to the acoustic performance of the Lionsgate Studio specification?

The acoustic performance of a roof can be enhanced by including products that add mass and increase sound absorption. The design of the roof assembly also needs to incorporate ways to decouple vibrational sound transmission paths to further limit the effect of outside noise on the internal environment.

Adding mass

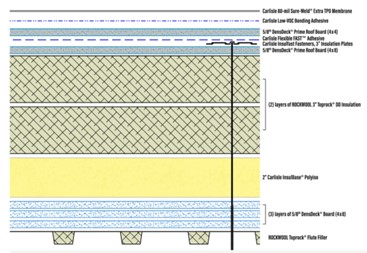

Mass was added over the roof deck by positioning three layers of acoustic flat roof board in the form of 15.9 mm (5/8”) thick DensDeck® Roof Boards, with each layer weighing around 12.2 kg/m2 (2.5 lbs/sq.ft). Two further layers of the same thickness and weight of DensDeck® Prime Roof Boards acted as a double cover board under the waterproofing membrane, adding further mass to the roof assembly.

Increasing sound absorption

The flutes of the metal deck were insulated with mineral fibre fillers and two layers of Rockwool mineral fibre insulation helped to increase sound absorption.

The mineral fibre insulation was positioned between the three layers of roof boards near the deck and the two layers of roof boards at the top of the assembly. The hard surface of one set of roof boards can cause any sound that penetrates it to bounce back inside the roof from the hard surface of the second set of boards. However, in this build-up the mineral fibre helped to absorb any sound making it through the roof boards, working in harmony with them to help control both the deep base noise from the trains and the higher pitched sound of their horns.

Decoupling

A long 12” mechanical fixing was used to secure the various layers of product to the metal deck. Two layers of DensDeck® Prime Roof Boards were positioned on either side of this fixing. One layer was held by the fixing itself. The second layer was adhered to the first, over the top of the fixing heads. This layer of adhesive between the two boards provides decoupling and reduces sound transmission through the fixing and overall assembly.

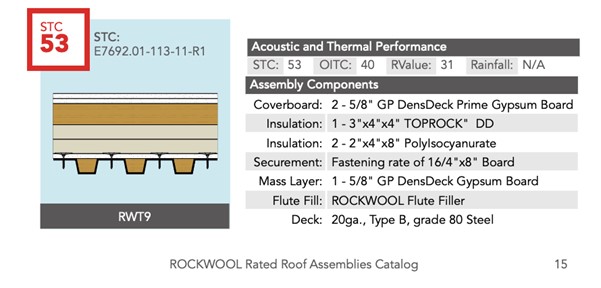

Lionsgate Studio, unlike the first building, was constructed under a design and build contract. This was implemented to make it a shorter and more flexible build process. When it came to the roofing design, the Nations Roof team was tasked with keeping the sound of the trains out of the building so a whole new specification approach was needed. After advice from acoustic consultants, a specification from Rockwool’s ‘Rated acoustic assembly catalogue’ for roof insulation was used as a starting point. This had an STC rating of 53 with 3 layers of DensDeck roof boards and one of mineral fibre.

This was improved by adding two extra layers of DensDeck Prime Roof Board and one extra layer of Rockwool.

As Joe points out: “Our highest performing acoustic roof assemblies was taken and then turned up to 11 to give the client the peace of mind that the roof would keep out the sound – and it did.”

Joe further explained the particular challenge posed by the location of the studio: “The studio was very close to trains that were producing sounds at both ends of the spectrum – both low and high pitched and that’s always more acoustically challenging to overcome. The blend of materials chosen provided added mass and sound absorption and was attached with decoupled fixings – it proved to be a winning combination.”

Roof assembly diagram from Nations Roof3

What is the acoustic plan for the roof of the third new studio at North Broadway?

Due to the outstanding acoustic qualities of the Lionsgate Studio, the same design approach has been taken when designing the acoustic performance of the roof assembly being built at the Great Point Studios facility in North Broadway.

Three layers of DensDeck® Roof Boards and a further two layers of DensDeck® Prime Roof Boards have again been specified along with the same configuration of insulation layers used in the Lionsgate studio roof. This will ensure that when Mediapro Studios opens later in the year at North Broadway, they will enjoy the same level of exceptional acoustic performance that is setting the new benchmark for studio roofs in Hollywood on the Hudson.

Besides acoustic performance what other benefits did DensDeck® Roof Boards bring to the project?

Although there were good acoustic reasons to include DensDeck® Roof Boards for the Lionsgate Studios project, their use also helps to increase the long-term resilience and robustness of the roof.

In their position under the waterproofing membrane and over the insulation layer, the fibreglass mat face of the roof cover boards helps adhesives to be applied uniformly and consistently, increasing material compatibility. This ensured that the TPO membrane used in the project had the best possible surface for adhesion, helping the bond strength and the resilience of the waterproofing layer.

The smooth, strong surface of the roof cover boards under the membrane, also provides the roof waterproofing with added puncture resistance against dropped tools or equipment that might occur during maintenance visits to the Lionsgate Studio roof. The cover boards also increase the resistance of the roof to damage by hail, providing welcome protection for the roof from the hailstorms that are a common occurrence in many parts of New York.

The gypsum core of DensDeck® Roof Boards contains crystallised water in its structure. In the unlikely event a fire would occur on the studio roof, the energy from the heat would vaporise the crystalised water. This creates a natural fire resistance that can help limit fire spread and penetration until it can be extinguished. As there are two layers of roof cover boards specified for this project this adds extra robustness to the fire-resistant properties of the roof and can help reduce losses in case a fire breaks out.

Carlisle Syntec Systems, who supplied the 80-mil Sure-Weld TPO membrane for the project, neatly summed up the contribution of the team of partners on the project4: “The team successfully delivered a strong, durable, soundproof roof system while protecting the building envelope.”

What award did the Lionsgate Studios project win?

Nations Roof, the roofing contractor for the Lionsgate Studios project, won the 2024 National Roofing Contractors Association (NRCA) Gold Circle Award5 in the innovative solutions category.

This recognises projects that have made significant contributions to the roofing industry. The Lionsgate Studios project showed that collaboration between leading industry manufacturers, installers and technical experts can provide solutions to meet the most exacting acoustic customer requirements. The products within the roof assembly combined to create a robust, resilient roof, to protect the studio from the noise, wind and weather of the outside world.

Chad Frank, Director- System Sales at Georgia-Pacific commented: “We were pleased that Georgia-Pacific provided cover boards for such an exciting and innovative project. It is rare that five layers of board are needed, however, the end result justifies their inclusion. We realised that the enhanced performance of DensDeck® Prime Boards was only needed for the top two layers under the waterproof membrane and recommended using DensDeck® Roof Boards for the triple layer over the deck to help reduce the cost for our customer.”

When John Geary was asked about the award he commented: “For us, the biggest accolade is always that we have another happy customer, but we were really pleased that the industry also recognised our efforts to build a great roof that keeps the sound out and sets a new acoustic standard for the studio industry”

Where can I find out more information about the acoustic and roof resilience properties of roof boards and cover boards for my next project?

If you are working on a flat roof design of a building with particularly challenging acoustic requirements such as a recording studio, airport, music venue contact the team at DensDeck® today. We will be happy to discuss how our products can enhance both the acoustic performance and roof resilience properties of your flat roof.

Send a project or specification enquiry

Start your project or simply get specification advice by dropping us a message.

One of our team will be in touch as soon as possible.