What is a typical metal standing seam roof build up?

What is a typical metal standing seam roof build up?

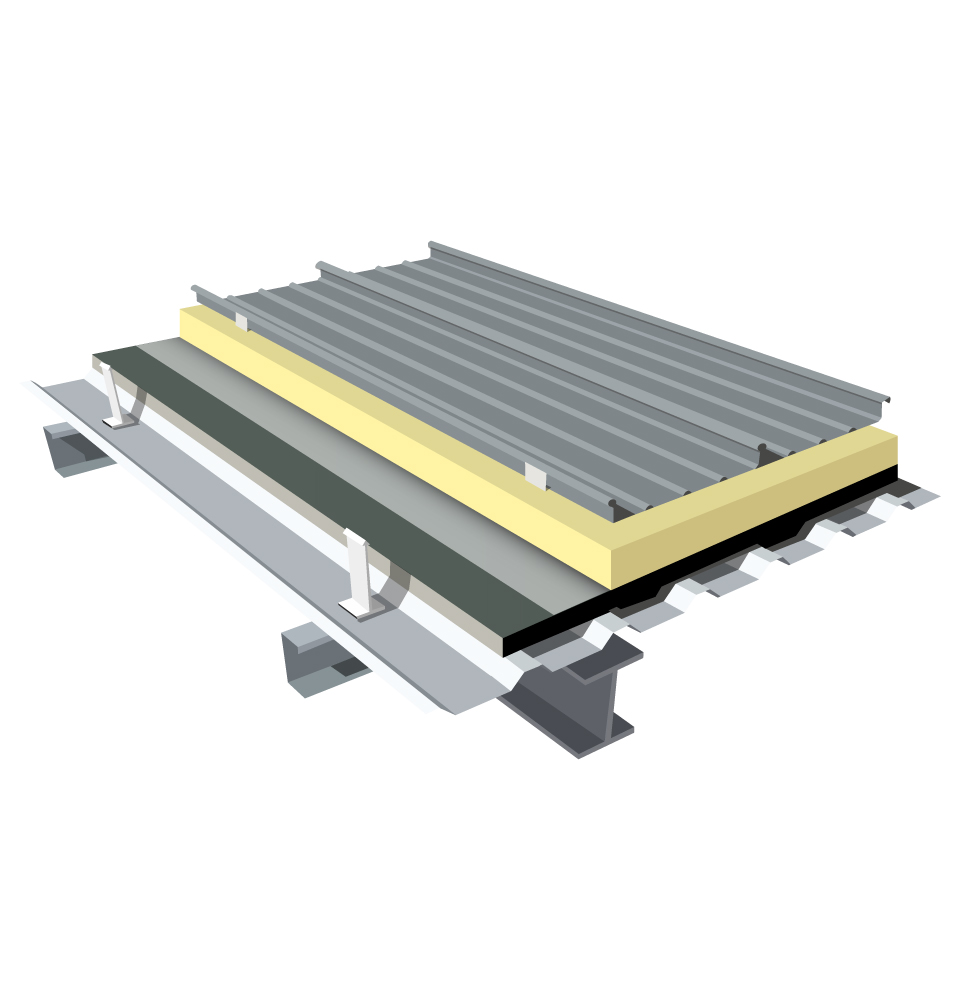

The typical roof build-up for a metal standing seam roof consists of a continuous metal or timber structural roof deck, a fully supported vapour control layer (VCL), an insulation layer and cover boards as a substrate for the top sheets or panels. The result is an aesthetically appealing, durable, and slim roof construction. Metal standing seam roofs are ideal for roofs with complex geometry, low maintenance, and extended design life requirements.

The name, metal standing seam roof, comes from how each panel connects to the next one. The raised connecting seams are raised above the roof level and appear to be standing. Various materials are used for metal standing seam roofs, including stainless steel, zinc, lead, and copper.

Both PIR insulation and mineral wool insulation are used within this type of roof build up individually or in combination. Notably, specification of mineral wool is significantly increasing in popularity. Project objectives will guide the insulation type specified. The substrate used above the insulation layer, the cover board, tends to be a lightweight fibre glass mat faced gypsum core board. Some build-ups will also use a roof board installed on the structural deck.

We will consider the reason for the specification of metal standing seam roof build-ups in commercial buildings before focusing on how the performance of this type of roof build-up can be improved.

What are the advantages and disadvantages of metal standing seam roof build-ups?

Metal standing seam roofs are growing in specification because they offer significant advantages for commercial projects:

- Durability

- Appearance

- Design flexibility

- Thermal efficiency of the roof build-up

The interlocking metal sheets, once installed, provide long lasting protection for the roof build-up components below. This is ideal for specification in large projects where durability and low maintenance are key specification drivers.

Metal standing seam roofs are popular with designers and architects seeking to deliver visually striking installations. The seams can be manufactured in different colours, profiles, and shapes. This type of roof offers aesthetic value through hidden fittings and design flexibility for even large scale installations.

Hamad International Airport, the most extensive stainless standing seam roof in the world

A standing seam roof profile can be curved or tapered to achieve a unique design, such as the roof of the Hamad International Airport in Doha by HOK. The architecturally significant undulating stainless steel roof of the passenger terminal establishes a connection with Qatar’s sand dunes and ocean waves. The total roof surface spans more than 217,000 m2.

The roof build-up consists of a steel deck, vapour control layer, Rockwool insulation, DensDeck® Prime Roof Board, Resisto membrane and the stainless steel standing seam roof covering. This build up was specified to support the high demand for customer comfort through high acoustic performance and customer safety with high fire safety performance requirements. You can read more about this project here.

What are the disadvantages of metal standing seam roof build ups?

The main disadvantage of a metal standing seam roof is that the installation is labour intensive and requires specialist installers. The aesthetic advantage of the hidden fixings and fasteners comes at the cost of the time it takes to install these. The spacing of the clips on the seam and fastening to the deck can take slightly longer if mineral wool insulation is specified for the roof build-up.

We already mentioned that metal standing seam roofs are long lasting, but they are vulnerable to damage from hail strikes and accidental damage by flying debris. FM (Factory Mutual) Global insurance groups classify hail strike zones within the US, where the insurance premiums are guided by satisfactory design parameters of the roof build-up being met.

It is worth noting that US based operators who are FM members will require FM approval for projects developed outside the US. Although FM approval for roofing components is not always a key specification factor, operators can favour FM approved products as they are quality and performance tested.

Which type of cover board improves the performance of metal standing seam roof build ups?

We already mentioned that roof and cover boards can increase specific performance markers of metal standing seam roofs. The right roof and cover board selection are crucial, and the light weight of gypsum core boards is advantageous over cementitious boards in this type of roof build-up. Where time and cost are of the essence, the lower weight of the roof build up means that less structural support is required. This means less material, less labour, and faster installation time.

How can DensDeck® Roof Boards increase the performance of metal standing seam roof build ups?

DensDeck® Roof Boards are high performance gypsum core boards with fibre glass mat facer, designed to improve performance, extend the design life, and minimise maintenance requirements of various roof build-up types.

Improving acoustic and fire performance of roofs through cover and roof board specification

DensDeck® Roof Boards can be used as cover boards, roof boards, or both placements. The exact acoustic and fire performance enhancement will vary depending on the placement of the boards within the roof build-up. Roof boards help limit the internal spread of fire as they are installed between the roof deck and the insulation layer, effectively creating a fire ‘break’. Cover boards increase the resistance of the roof assembly to external fire sources. Albeit metals sheet is not likely to propagate this type of fire, cover boards can still be installed beneath them to offer additional protection.

Cover boards and roof boards are increasingly installed on steel roof decks to improve acoustic performance. If both sound attenuation and sound absorption are required, then DensDeck® Roof Boards are likely needed both on the roof deck and above the insulation layer. DensDeck® Roof Boards have been tested and classified to have an A1 reaction to fire in accordance with BS EN 13501-1. The boards have been acoustically tested in various roof build ups to confirm performance enhancement levels.

Cover boards increase the resistance of roof build-ups to hail strikes, punctures, and wind uplift

DensDeck® Roof Boards act as a homogenous substrate for the metals standing seams to be fixed to. When appropriate fitting and clips are used, the presence of a cover board with a high vertical pull value increases the resistance of the entire roof build to wind uplift. The substrate also improves the resistance to repeated hail strikes and damage by flying debris some types of metal standing seam roofs can be vulnerable to.

Cover boards and enhanced dimensional stability and roof access

The standing seam installation is one of the most time consuming elements of the roof assembly. DensDeck® Roof Boards installed as cover boards protect compressible insulation during the installation phase. The cover boards continue to protect the roof assembly from mechanical loading once the installation is complete

Contact us to find out more about DensDeck® Roof Boards and the benefits for your metal standing seam roof.

Contact Us

Start your project or simply get specification advice by dropping us a message.

One of our team will be in touch as soon as possible.